I know that allot of bigger trailers and semi trailers are using oil bath Oil bath vs Grease hubs for boat trailer I need a new axle on my boat trailer and called the manufacturer oil bath for 280 or grease for 332 plus shipping. Regular grease trailer bearing parts are easy to find just about everywhere.

I currently have oil bath hubs on my trailer.

Oil bath trailer hubs vs grease. Axles hauling trailersToday we dive into oil bath axles and grease axles to see which one is the overall better lubrication system for your trailer. A side by side comparison of maintenance on an oil bath hub and a grease hub. The oil bath is on a Dexter 10K axle and the grease hub is on a 7K Lippert axle.

Grease packed hubs vs oil bath hubs. They have both been around forever but which one is better. Here at Marlon we prefer grease packed hubs over oil bath hubs for a couple of simple reasons.

If you have a seal go bad you wont lose all your lubricant in a matter of seconds. Pritchard sees a higher failure rate of oil bath hubs especially with boat trailers and would go with the grease packed hubs every time. They are the only way to go for greater reliability and.

U can easily see if your bearings have lube and spot problems sooner. Grease will let things sneak up on you. Oil lubes much better however u can have a seal leak and loose your oil real fast while grease will stay in.

When i was in the shop grease bearings failed much more than oil. I replaced 10 grease to 1 oil. Just make a stedfast routine of peekin at your oil level everyday and watch the inside of.

I currently have oil bath hubs on my trailer. I am looking to swap over to grease zerk stylehubs. The reason i am looking to switch is i can not get these hubs to stop leaking.

I have tried all types of sealants gasket material and they still leak and or push half way out on longer trips to the point where i carry a rubber mallet and a 2x4. I know that allot of bigger trailers and semi trailers are using oil bath Oil bath vs Grease hubs for boat trailer I need a new axle on my boat trailer and called the manufacturer oil bath for 280 or grease for 332 plus shipping. I was told and found out that if you do not run it for a while the oil will settle to the bottom and leave the top of the bearing dry.

The bearing will rust do to the moisture that is in the cap. I kept my grease and added the synthetic style grease. I think that a boat trailer will be worse due to the water getting in and foaming out the oil.

Stay with the grease hubs and get you some bearing buddies or red-eye protectors do your annual preventative maintenance and you will never have an issue - oil bath and the hypoid grease systems that say no maintenance are misleading - never had a failure with the standard grease set up and repacking every year - and I have towed from NV to FL and make numerous 6-10 hr trips towing. Regular grease trailer bearing parts are easy to find just about everywhere. The greatest advantage to grease bearings however is probably their stubbornness.

When a bearing first starts to go grindy it will often keep on spinning long after the problem arises allowing you to make way for a repair shop or get back to your driveway instead of leaving you on the shoulder. The main reason people like oil bath hubs over grease hubs is the oil bath hubs have a less involved maintenance schedule than grease hubs. It is recommended to inspect and repack grease wheel bearings and seals every 12k miles.

With oil bath hubs Dexter recommends to periodically check and refill when necessary. The hubs on the trailer are oil bath. He lost the oil in one hub once frying the bearings in that hub quickly.

I understand his load conditions are way more extreme than any load condition our trailers are subjected to. Bearings will run cooler with a oil bath systembut if you have a seal go out oil will just run out leaving very little lubricantIf a seal goes out with greased hubs at least the bearings will be lubedOil bath systems are easier to change lube though and if you keep an eye on themwork wellI personally think if you have a larger heavier rig like a large bass boat or walleye boat like a ranger 621 I would go. Actually all you really have to do is remove the oil from the hub and then pack the hubs with grease and then get the correct bearing buddy to match the threaded hub bore.

You will need to measure the inner diameter of where the old grease cap installed on your hub to. One other issue in oil vs. Grease is if you have a cover blowoutfailure while on a long trip without stopping is that the grease type hub will get you there without a hub failure.

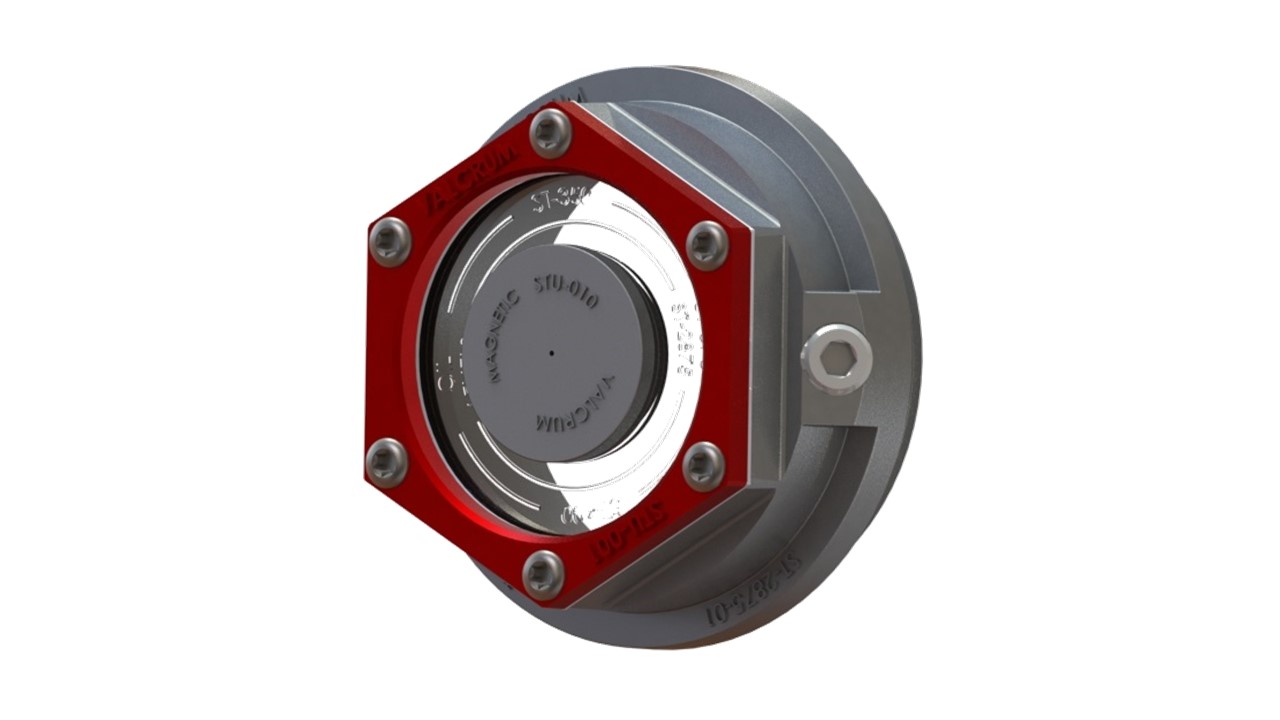

The oil hub will blow all the thin oil out of the hub fairly quick and you will end up with a major bearing and or hub failure leading to the dreaded boat on the side of the road syndrome if it is not caught pretty soon after the. I really like these seals they cost more but they do an excellent job of oil control the only disadvantage is if you remove the hub the seal is probably not going to be reusable my ratio is about 5050 but careful patient disassembly helps. I highly recommend this seal for hub rotors that are oil bath not for drums that are grease and need removal to change brakes.

The grease-packed bearings arent as susceptible to total loss of lubricant. When theyre right though the oil bath bearings do a better job of lubricating than the grease without the frictional losses of the heavier grease. Theres a reason that most.

You can convert some hubs from grease to oil bath using a kit such as XLPROLUBE1980KIT but for others it would not be possible without changing the hubs. This is because oil bath hubs use an oil cap that threads onto the end of the hub. Most regular hubs are not threaded so you would not be able to screw on an oil cap.

The other problem is that when a seal goes out in a grease hub you can make it home typically to replace the seal without damaging the bearings or hub whereas with a oil-bath system once you lose a seal all of the lubrication disappears and you have to park the trailer till you get the correct replacement parts. An oils viscosity is correlative to the film thickness it can create. This thickness is crucial to the separation of the rolling and sliding elements in a bearing.

Bearings in some applications use oil but grease is the lubricant of choice for 80 to 90 of bearings. Grease consists of about 85 mineral or synthetic oil with thickeners. Wheel bearings - Why I use oil instead of grease.

Oil systems tend to be more expensive than grease both in terms of initial investment and maintenance requirements. There are potential issues involving oil leakage and disposal. The labor required to maintain appropriate levels is greater with oil than with grease.